Korbwand®

big

medium

detail

Idea

“Semi-automated work makes life easier for employees on construction sites. Yet one of the most long-winded activities – putting together steel bars for reinforcement cages – almost always has to be carried out manually in construction site work.

At the same time, double walls are still reinforced with lattice girders according to standard EN14992 and always produced using formwork. This is obviously no longer up to date. In my search for solutions, I came across many inventions that were not really mature and so had not been accepted by the market. I simply could not believe that it was impossible and went looking for welded cages.

The oldest patent I found was dated 1963. Suggestions were given in many talks as to which system I should analyse and what the sector really needs. I came across numerous interesting methods – forgotten in the course of time – but which again and again opened the door to new ideas.

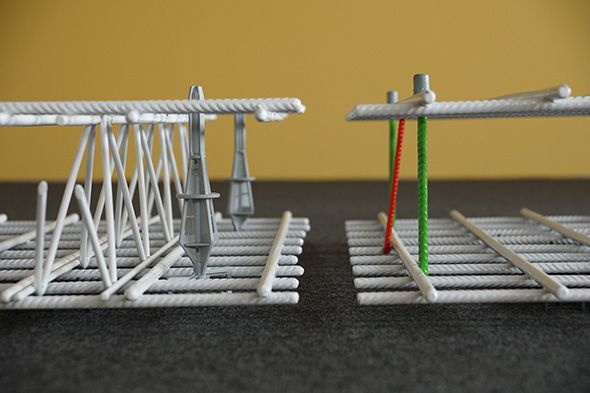

My first idea was to integrate a cage welding machine into an existing mesh welding machine. I also made the assumption that the number of welded bars and diagonals always had to be identical. Today we know that just a tenth of the bars is entirely sufficient.

It was only in 2014, when I first gained insight into the world of welding robots, that I found a way of implementing my idea. Things then started to move at a rapid pace, even if specific ideas as regards a finished system would be changed several times. I was finally able to put my vision into practice with the support of the Technical Building Institute Linz (BTI) and MABA, precast concrete component producers.”

Hubert Rapperstorfer

Advantages for Manufacturers

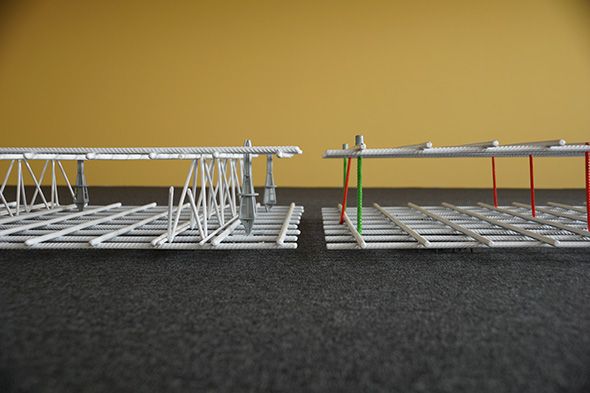

The innovative Rapperstorfer Automation system makes it possible to manufacture concrete cages in a fully automated and entirely individual manner. By solidly welding the bars for connecting individual meshes, a double cage wall achieves greater stability whilst saving on materials. The chaos of bars between the meshes has been replaced by a clearly defined number.

Production in lot size 1 is made possible with this system, which is a great advantage with individual structures in particular. This means that the system can be utilised both in precast component construction and in individual areas as well.

The savings on time and material are considerable especially with large quantities of Korbwands. Investment in the system is paid back quickly.

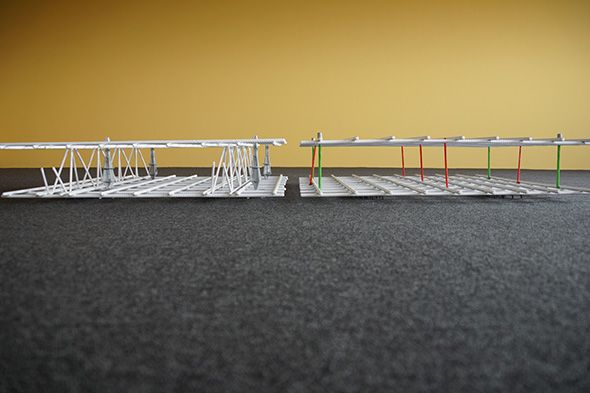

greater stability

enhancing stability

Advantages for Consumers

The Korbwand® is delivered complete to a construction site and can be concreted out immediately. Additional processing with the lattice girders or delays is no longer necessary. The Korbwand® arrives tailor-made at a construction site. Savings can be made on the bars by means of precise structural design calculations. This reduces weight and costs whilst at the same time substantially enhancing stability. Besides this, it is structurally possible to achieve more rapid filling times through a targeted increase in the number of bars.

Application

Double walls according to EN14992 are nowadays the undisputed standard in civil engineering. Precast component construction work can scarcely be made more efficient. In its functionality, the Rapperstorfer Korbwand® is a classic double cage wall. The great difference to classic cages, however, is its fully automated and entirely individual manner of production in lot size 1, the elimination of time-consuming post-processing work at construction sites, and the appreciably more efficient utilisation of materials. The Korbwand® gives greater stability whilst saving on time and money.

more efficient

Unser Komplettangebot

Our Comprehensive Product Range

Rapperstorfer Automation produces the comprehensive system for manufacturing reinforcing cages. The fully automated production of each Korbwand® in a form you yourself have defined is entirely in your hands – from its starting material, reinforcing steel (in rolls), to the finished product on a construction site. All transportation and production elements have been built into the system. All you need is steel, electricity and a Rapperstorfer Automation System.